So, finally there is some power in. Not very much power because I still need to get the rest of the RCBO's.

I dug a trench for the power cable and put the earth rod down.

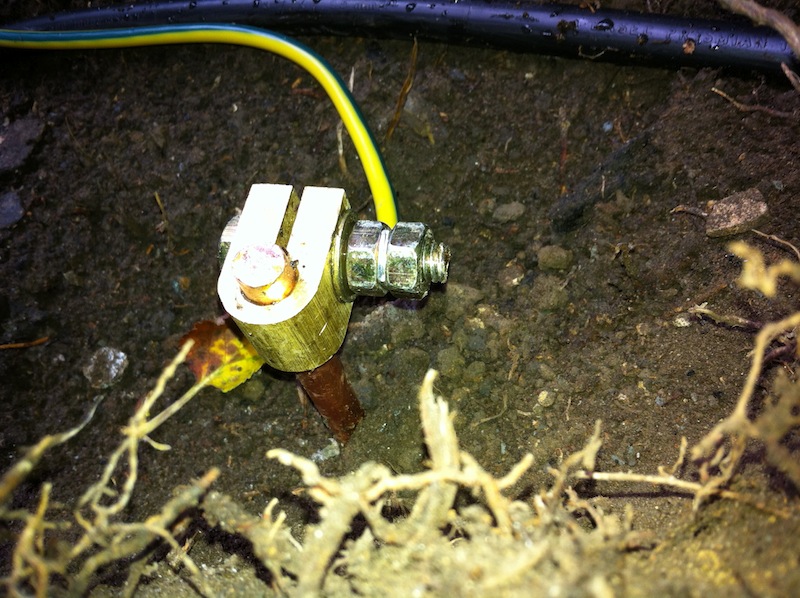

Here is the 1.2 metre earth rod smashed in and a 10mm cable attached.

Then, as SeanB suggested, the clamp is covered with grease, a finger from a rubber glove goes over that and then self amalgamating tape over the lot. This prevents corrosion.

Now, if there are any Health and Safety police about, please do take the day off. I am well aware that my board looks poorly installed, but is not complete by any stretch of the imagination. It is working for now and it is providing protection and has only got to run a lamp for the moment.

I plan to mount the Consumer Unit on a hinged board to that I can bring the cables in and out from behind it. This also makes it easier to perform modifications in the future.

All it has now are a 100A incomer and a 6A RCBO. The incomer is what was supplied with the Consumer Unit, the cable is protected appropriately at the head end.